AI Chip Supply Chain Risk in 2026: What the 2025 Chip Wars Taught Enterprise Leaders

AI Supply Chain Risk 2026: From Cloud Utility to Constrained Physical Resource

The 2025 AI chip wars forced a strategic re-evaluation, shifting the enterprise view of AI infrastructure from a scalable cloud service to a constrained, physical, and geopolitically sensitive resource. The primary lesson learned is that the AI supply chain is no longer a backend operational concern but a central pillar of corporate strategy, where physical constraints, not just algorithms, dictate the pace of innovation and competitive advantage.

- Between 2021 and 2024, enterprise focus was on algorithmic development and deploying models via cloud providers, assuming compute was an infinitely scalable utility. After the ‘silicon shock’ of 2025, the primary constraint became physical hardware availability, forcing leaders to confront the tangible limits of the supply chain.

- The crisis revealed that the main chokepoints had migrated downstream from silicon fabrication. By 2025, TSMC identified advanced packaging, not wafer production, as the industry’s true bottleneck, directly impacting the supply of high-margin GPUs from Nvidia and Broadcom.

- Simultaneously, the surge in AI data centers created an “unprecedented” shortage of high-bandwidth memory (HBM). Memory provider Micron Technology stated the shortage is expected to last beyond 2026, creating cost inflation for all electronics and making memory players a clear financial winner of the AI boom.

- This shift forces executives to engage in long-term capacity planning that accounts for factors previously abstracted away by the cloud, including data center availability, cooling constraints, and grid access for power, which are now ultimate bottlenecks for AI deployments.

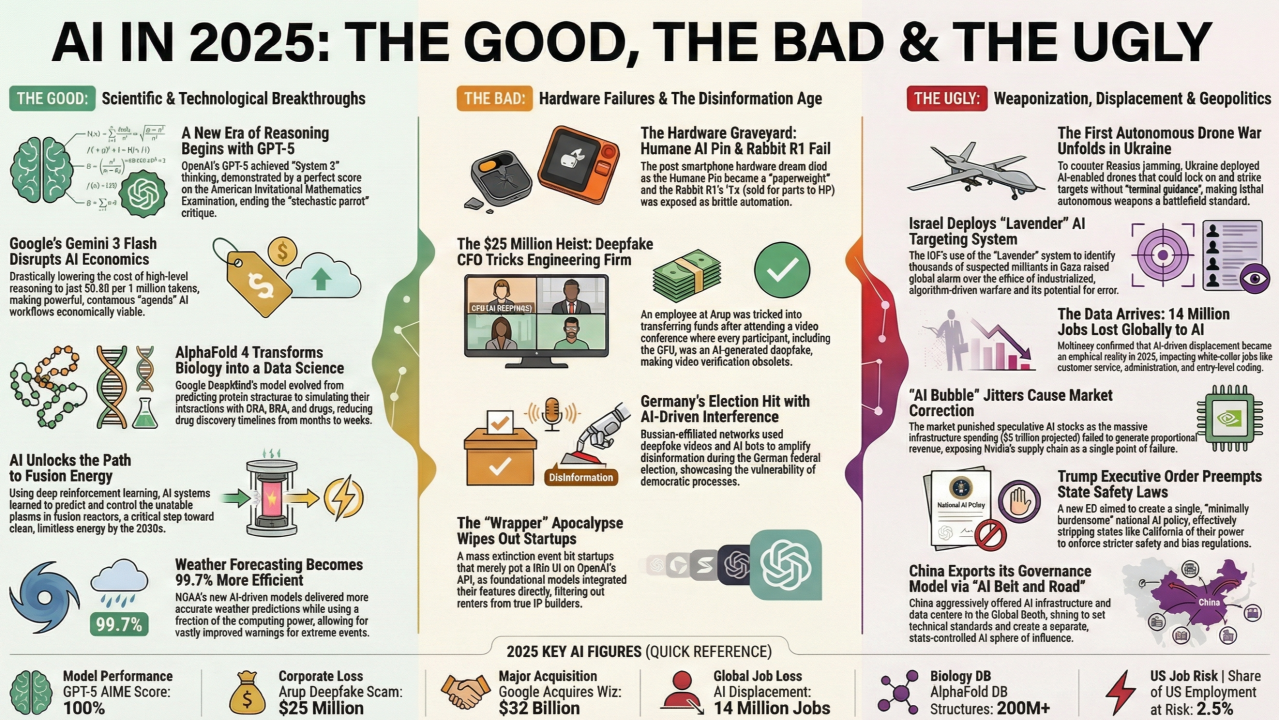

2025 Review Highlights Nvidia Supply Chain Failure

This chart illustrates the “silicon shock” referenced in the text, identifying Nvidia’s supply chain as a single point of failure that validated the shift to viewing AI infrastructure as a constrained physical resource.

(Source: LinkedIn)

Geopolitical Reshoring: Analyzing the Trillion-Dollar Investment Shift in AI Chip Manufacturing

Geopolitical friction and supply chain vulnerabilities triggered a massive, multi-trillion-dollar investment cycle to diversify manufacturing, shifting capital from “just-in-time” efficiency to “just-in-case” resilience. This wave of investment, catalyzed by government incentives, is fundamentally redrawing the global map for advanced semiconductor production.

Semiconductor Market to Surpass $1 Trillion

This forecast aligns with the section’s “trillion-dollar investment shift” theme, showing the immense market value driving massive capital reallocation and geopolitical reshoring efforts in chip manufacturing.

(Source: Deloitte)

- The scale of capital reallocation is immense, with the U.S. CHIPS and Science Act alone catalyzing over $630 billion in private investments to bolster the domestic supply chain. This is a direct response to the risks exposed in 2025 by the industry’s heavy reliance on East Asian manufacturing.

- Major corporations have committed staggering sums to build new fabrication and packaging facilities on U.S. soil. Key commitments include Nvidia‘s plan to invest $500 billion, TSMC‘s increased investment to $165 billion for new fabs in Arizona, and Intel‘s $100 billion plan to expand its domestic capacity.

- This strategic pivot toward “friend-shoring” and reshoring is not limited to the United States. In Europe, Intel has outlined plans for an €80 billion (approximately $88 billion) investment, while in Asia, China established a $47.5 billion fund to counter U.S. restrictions and achieve semiconductor self-sufficiency.

Table: Major U.S. Semiconductor Investment Commitments (2025-2026)

| Partner / Project | Time Frame | Details and Strategic Purpose | Source |

|---|---|---|---|

| Nvidia | From 2025 (next four years) | Announced plans for a $500 billion investment in U.S. manufacturing and AI infrastructure, including a partnership with TSMC in Arizona, to secure its supply chain. | NVIDIA Plans to Invest $500 Billion in US Manufacturing |

| TSMC | 2025 onwards | Increased its U.S. investment to $165 billion for the expansion of advanced semiconductor manufacturing in Arizona, including new fabs and advanced packaging facilities to address the industry’s primary bottleneck. | The $3 Trillion Race: Investing in Semiconductors for an AI- … |

| Intel | 2025 onwards | Committed $100 billion to increase domestic chip manufacturing capacity and capabilities, directly supported by CHIPS Act funding, positioning itself as a key foundry alternative to TSMC. | Artificial Intelligence (AI) Chipsets Market Size & Share, 2032 |

| Global Foundries | 2025 onwards | Announced a $16 billion investment plan to strengthen U.S. semiconductor leadership and reshore essential chip manufacturing, focusing on diversifying the domestic ecosystem. | Global Foundries Announces $16 B U.S. Investment to … |

Strategic Alliances in the AI Chip Wars: How Partnerships Are Redefining Supply Chain Moats

The chip crisis made deeply integrated, long-term partnerships a primary tool for securing supply, replacing transactional procurement with strategic co-development and ecosystem-building. In a supply-constrained world, enterprises and hyperscalers are forming alliances that span the entire value chain to mitigate risk and avoid vendor lock-in.

Chart Outlines Five Strategic AI Archetypes

This chart provides a framework for the “strategic alliances” and “supply chain moats” discussed, categorizing companies by their competitive strategies in the evolving AI ecosystem.

(Source: The Business Engineer)

- The over-reliance on Nvidia and TSMC created systemic vulnerabilities that companies are actively mitigating through diversification. For example, Meta is exploring the use of Google‘s TPUs for its data centers planned for 2027, signaling a market shift toward multi-architecture strategies.

- Co-development has emerged as a key strategy for securing proprietary access to technology. Open AI is reportedly partnering with Broadcom and TSMC to develop its own custom AI chip, aiming to reduce its dependence on third-party suppliers for its future models.

- Foundry diversification is now a critical de-risking tactic. With TSMC‘s capacity stretched, Intel has emerged as a vital alternative, securing a major partnership with Amazon Web Services (AWS) to manufacture a custom AI chip using its advanced 18 A process node.

- To counter Nvidia‘s dominant CUDA software platform, competitors are building open ecosystems. Intel is leading an “AI Open Systems Strategy” with partners like Google and Dell to create an open, multi-vendor alternative for enterprise AI, reducing the risk of a single point of failure.

Table: Critical Partnerships in the AI Chip Ecosystem (2024-2026)

| Partner / Project | Time Frame | Details and Strategic Purpose | Source |

|---|---|---|---|

| Open AI, Broadcom, TSMC | Expected 2026 | Co-development of a proprietary AI chip for Open AI. This strategic move aims to reduce reliance on third-party suppliers like Nvidia and create hardware optimized for its specific model architectures. | Inside Open AI’s First AI Chip Venture with Broadcom and … |

| Intel, Amazon Web Services (AWS) | Announced Sep 2024 | Foundry services partnership where Intel will manufacture a custom AI fabric chip for AWS. This diversifies AWS‘s supply and validates Intel‘s strategy to become a major alternative foundry. | Intel and AWS Expand Strategic Collaboration, Helping … |

| Nvidia, TSMC, Synopsys | Announced Mar 2024 | Technology integration to deploy Nvidia‘s cu Litho computational lithography platform. This partnership aims to accelerate the manufacturing process at TSMC, addressing production speed as a key constraint. | TSMC and Synopsys Bring Breakthrough NVIDIA … |

Silicon Sovereignty: How the AI Chip Wars Redrew the Global Manufacturing Map

The AI chip wars accelerated a global restructuring of the semiconductor supply chain, with the United States and Europe launching massive investment programs to counter decades of manufacturing concentration in East Asia. The pursuit of “silicon sovereignty” became a central pillar of national industrial policy in response to the vulnerabilities exposed in 2025.

- Prior to 2025, the world’s most advanced chips were overwhelmingly manufactured in a few locations, primarily by TSMC in Taiwan. The 2025 shortages made clear that this geographic concentration posed an unacceptable risk to economic and national security for major economies.

- The United States initiated the most aggressive diversification effort, leveraging the CHIPS and Science Act to attract monumental investments. This includes TSMC‘s $165 billion complex in Arizona, Intel‘s $100 billion U.S. expansion, and SK hynix‘s $3.87 billion advanced packaging plant in Indiana.

- Europe is executing a similar strategy with its own Chips Act. Intel‘s commitment to invest over €80 billion across the continent, anchored by a “mega-fab” complex in Germany, is designed to rebuild Europe’s semiconductor manufacturing capabilities.

- These Western initiatives prompted counter-moves in Asia. China established a new $47.5 billion state-backed fund, its largest yet, to accelerate its drive for self-sufficiency, while South Korea announced a $7 billion investment to protect its leadership in memory and advanced chip manufacturing.

Beyond the Wafer: Why Advanced Packaging and HBM Became the AI Era’s Defining Technologies

By 2025, the critical technology bottleneck for AI performance shifted decisively from leading-edge silicon fabrication to the less mature but equally vital domains of advanced packaging and high-bandwidth memory. This maturation of constraints revealed the true, multi-layered dependencies of the high-performance computing supply chain.

- In the period from 2021 to 2024, the industry narrative focused on the progression of lithography nodes (e.g., from 7 nm to 3 nm). By 2025, key industry leaders like TSMC publicly confirmed that the primary constraint was no longer wafer production but the capacity for advanced packaging.

- This shift occurred because top-tier AI accelerators from Nvidia and Broadcom require sophisticated packaging techniques to integrate multiple chiplets into a single high-performance unit. Specialized technologies like Co-Packaged Optics and glass core substrates are not easily scaled, creating a severe supply chokepoint.

- The “memory crunch” emerged as another critical technology challenge. The performance of large AI models is directly tied to the massive data throughput provided by HBM. As AI data center construction surged, memory demand accelerated faster than supply, leading Micron to forecast shortages extending beyond 2026.

SWOT Analysis: Strategic Positioning in the 2026 AI Chip Supply Chain

The AI chip market’s strengths in innovation and demand are now balanced by severe weaknesses in supply chain concentration and threats from geopolitical friction, forcing a strategic realignment toward opportunities in diversification and resilience. The crisis of 2025 served as a validation point, resolving prior assumptions about supply chain stability and exposing new vulnerabilities.

- Strengths were redefined from ecosystem dominance to the sheer scale of demand and capital inflow.

- Weaknesses shifted from known concentrations to newly exposed bottlenecks in packaging and talent.

- Opportunities emerged directly from the crisis, creating new markets for foundry alternatives and diversification strategies.

- Threats escalated from theoretical trade tensions to direct, impactful export controls and physical infrastructure delays.

Table: SWOT Analysis for the AI Chip Supply Chain

| SWOT Category | 2021 – 2023 | 2024 – 2025 | What Changed / Resolved / Validated |

|---|---|---|---|

| Strengths | Dominance of Nvidia‘s CUDA software ecosystem and TSMC‘s manufacturing process leadership created a powerful, efficient, but concentrated market. | Unprecedented, validated market demand for AI chips, driving massive capital inflows and government support (e.g., CHIPS Act) for expansion. The AI market is projected to reach over $450 billion by 2032. | The market’s immense value was validated, but the strength of a concentrated ecosystem was revealed to be a systemic vulnerability, prompting a shift toward a multi-polar, resilient model. |

| Weaknesses | High geographic and supplier concentration was a known but accepted risk, with heavy reliance on TSMC for manufacturing and Nvidia for GPUs. | The true bottlenecks were exposed: limited advanced packaging capacity and a severe shortage of HBM memory. A critical shortage of skilled labor to build and operate new fabs was also identified. | The weakness was not just concentration but a lack of visibility into downstream dependencies. The 2025 crisis validated that the supply chain is a fragile, multi-layered system, not a monolith. |

| Opportunities | Focus on designing better AI models and leveraging existing cloud infrastructure. Custom silicon efforts (e.g., Google‘s TPU) were viewed as optimization, not necessity. | Urgent diversification created massive opportunities for alternative foundries (Intel), GPU architectures (AMD), and custom silicon designers (Broadcom). AI is now being used to optimize the supply chain itself. | The crisis created a market for resilience. This validated the business case for Intel‘s foundry services, multi-foundry strategies (e.g., Tesla), and open-source software ecosystems to counter CUDA. |

| Threats | Geopolitical tensions and trade friction were emerging concerns, but their direct impact on enterprise supply was less immediate. | Escalating U.S. export controls on AI chips to China created market fragmentation. Physical infrastructure—grid access, permits, labor—became a primary threat to the speed of the buildout. | Geopolitical risk transformed from a background threat into a primary driver of corporate and national strategy. The threat is no longer just trade policy but the physical impossibility of building and powering new capacity quickly enough. |

2026 Forward Outlook: Navigating the Physical Constraints of the AI Infrastructure Buildout

Moving into 2026, enterprise success will be defined by the ability to secure physical resources, where the primary indicator of advantage is no longer just access to algorithms but guaranteed access to power, data center capacity, and the complete hardware stack. The “silicon shock” of 2025 taught leaders that AI is a physical, not virtual, domain.

- If this happens: If demand for AI hardware continues to outstrip the new, multi-billion-dollar manufacturing capacity scheduled to come online post-2026, the competition for resources will intensify further.

- Watch this: Watch for hyperscalers like Microsoft, Amazon, and Google using their balance sheets and long-term planning to secure not just chip allocations but entire infrastructure pathways, including multi-year power purchase agreements and priority access to data center construction pipelines.

- These could be happening: We could see continued price inflation for all electronic gadgets as AI demand consumes available memory and packaging capacity. Enterprises without a clear, long-term physical infrastructure strategy for their AI initiatives will face significant competitive disadvantages, as access to compute becomes the definitive barrier to innovation.

Frequently Asked Questions

What was the biggest lesson for enterprise leaders from the 2025 AI chip wars?

The primary lesson was that AI infrastructure is not an infinitely scalable cloud service but a constrained, physical, and geopolitically sensitive resource. The ‘silicon shock’ of 2025 demonstrated that physical hardware availability, not just algorithms, is the main factor limiting innovation, making supply chain management a central pillar of corporate strategy.

What are the new main bottlenecks in the AI chip supply chain?

The main bottlenecks have shifted downstream from silicon fabrication. The two critical chokepoints are now advanced packaging, which is needed to assemble high-performance GPUs, and High-Bandwidth Memory (HBM). The surge in AI data centers created an ‘unprecedented’ shortage of HBM that is expected to continue beyond 2026.

Why are companies and governments investing trillions in reshoring chip manufacturing?

These massive investments are a direct response to the supply chain vulnerabilities and geopolitical risks exposed by the heavy concentration of chip manufacturing in East Asia. The goal is to achieve ‘silicon sovereignty’ and shift from a ‘just-in-time’ efficiency model to a ‘just-in-case’ resilience model by building new fabrication and packaging facilities in the U.S. and Europe, spurred by government incentives like the CHIPS Act.

How are companies trying to reduce their dependence on Nvidia?

Companies are using a multi-pronged strategy to mitigate over-reliance on Nvidia. This includes diversifying hardware suppliers (e.g., Meta exploring Google’s TPUs), co-developing custom chips (e.g., OpenAI partnering with Broadcom and TSMC), and diversifying foundries (e.g., AWS partnering with Intel). Competitors are also building open software ecosystems to create a viable alternative to Nvidia’s dominant CUDA platform.

Beyond chips themselves, what are the biggest constraints for AI deployment in 2026?

The biggest constraints are now physical infrastructure. As AI deployments scale up, the ultimate bottlenecks are data center availability, access to the power grid for electricity, and adequate cooling solutions. The article states that enterprise success in 2026 will be defined by the ability to secure these physical resources, as AI has become a physical, not virtual, domain.

Experience In-Depth, Real-Time Analysis

For just $200/year (not $200/hour). Stop wasting time with alternatives:

- Consultancies take weeks and cost thousands.

- ChatGPT and Perplexity lack depth.

- Googling wastes hours with scattered results.

Enki delivers fresh, evidence-based insights covering your market, your customers, and your competitors.

Trusted by Fortune 500 teams. Market-specific intelligence.

Explore Your Market →One-week free trial. Cancel anytime.

Related Articles

If you found this article helpful, you might also enjoy these related articles that dive deeper into similar topics and provide further insights.

- E-Methanol Market Analysis: Growth, Confidence, and Market Reality(2023-2025)

- Battery Storage Market Analysis: Growth, Confidence, and Market Reality(2023-2025)

- Carbon Engineering & DAC Market Trends 2025: Analysis

- Climeworks 2025: DAC Market Analysis & Future Outlook

- Climeworks- From Breakout Growth to Operational Crossroads

Erhan Eren

Ready to uncover market signals like these in your own clean tech niche?

Let Enki Research Assistant do the heavy lifting.

Whether you’re tracking hydrogen, fuel cells, CCUS, or next-gen batteries—Enki delivers tailored insights from global project data, fast.

Email erhan@enkiai.com for your one-week trial.